16mncr5 case hardening steel

16mncr5 case hardening steel

Specification

16MnCr5 Carburizing steel. DIN 16MnCr5 gear steel is DIN standard Alloy Carburizing gearing steel, its properties is a chromium, manganese, titanium alloy steel specification. 16MnCr5|1.7131 is equivalent with others standard Carburizing steel, gearing steel.

Application

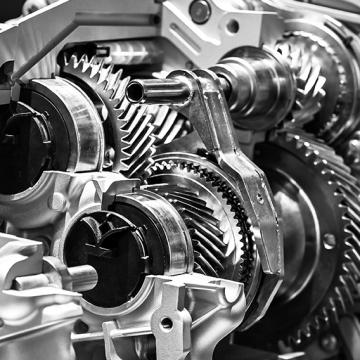

DIN 16MnCr5|1.7131 steel is widely used for a variety of applications in the used to the gearings in rotating machinery. Typical applications such as valve bodies, pumps and fittings, the high load of wheel, bolts, double-headed bolts, gears, internal combustion engine. Electric locomotives, machine tools, tractors, steel rolling equipment, boring machine, railway vehicle, and mining machinery transmission shaft on the steel ball, roller and shaft sleeve, etc.

Chemical Analysis %

| C | Mn | Cr | Si | P | S |

|---|---|---|---|---|---|

| 0.14-0.19 | 1.00-1.40 | 0.80-1.30 | 0.40 MAX | 0.035 Max | 0.035 Max |

Delivery condition

Annealed 248 HB max

Heat Treatment

| Soft Annealing | Cooling | Stress Relieving | Carburizing | Case Hardening | Quenching | Hardness after quenching HRC |

|---|---|---|---|---|---|---|

| 790°-810°C | Furnace | 800°-810°C | Pack, salt or gas carburize at 880°C | 780°-820°C | Air, oil, salt bath 650°-700°C | 60 |

Tempering °C

| Tempering°C | 100 | 200 | 300 | 400 | 500 | 600 |

|---|---|---|---|---|---|---|

| HRC | 60 | 52 | 52 | 54 | 56 | 50 |