SAE 8620 Case hardening steel DIN 21nicrmo2

SAE 8620 Case hardening steel DIN 21nicrmo2

Specification

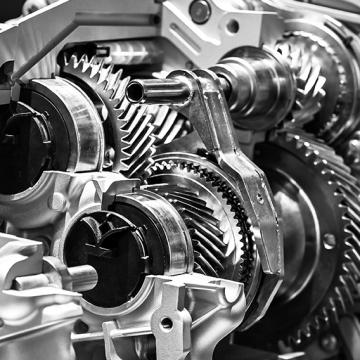

This grade is a low alloy nickel, chromium, molybdenum case hardening steel. Carburised8620 gives a hard case with a strong core whilst retaining a remarkable degree of toughness. SAE 8620 is suited for applications which require a combination of toughness and wear resistance.

Application

Typical uses are: Arbors, Bearings, Bushings, Cam Shafts, Differential Pinions, Guide Pins, King Pins, Pistons Pins, Splined Shafts, Ratchets, Sleeves etc.

Chemical Analysis %

| C | Mn | Cr | Si | Mo | P | S | Ni |

|---|---|---|---|---|---|---|---|

| 0.17-0.23 | 0.60-0.95 | 0.35-0.75 | 0.10-0.40 | 0.15-0.25 | 0.040 Max | 0.040 Max | 0.040 Max |

Delivery condition

Annealed 240 HB max

Heat Treatment

Annealed 240 HB max

Heat Treatment

| Soft Annealing | Cooling | Stress Relieving | Carburizing | Refine | Case Hardening | Quenching | Hardness after quenching HRC |

|---|---|---|---|---|---|---|---|

| 820-850°C | Furnace | 630°-650°C | Pack, salt or gas carburize at 880°C – 930°C | 850°-880°C | 780°-820°C | Air, oil 820°-840°C | 60 |

Tempering °C

| Tempering°C | 100 | 200 | 300 | 400 | 500 | 600 | 700 |

|---|---|---|---|---|---|---|---|

| HRC | 60 | 52 | 52 | 54 | 56 | 50 | 32 |