EN-353 steel DIN 20nicrmo5

EN-353 steel DIN 20nicrmo5

Specification

Nickel chromium molybdenum high tensile steel, has good wear and shock resistance and is suitable for tensile ranges up to 1550N/mm². ASTM EN24 steel is an alloy structural steel, EN24 is used for engineering structural, Used as require good toughness, high strength, as well as the important conditioning of large size.

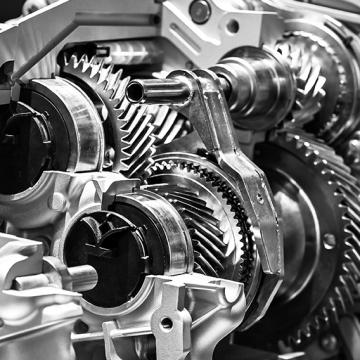

Application

Uses for many automobile applications like heavy duty gear, shaft, Machining components, pinion, camshafts, gudgeon pins.

Chemical Analysis %

| C | Mn | Cr | Si | MO | Ni | P | S |

|---|---|---|---|---|---|---|---|

| 0.10-0.20 | 0.50-1.00 | 0.75-1.25 | 0.10-0.35 | 0.20-0.35 | 1.00-1.50 | 0.040Max | 0.040Max |

Delivery condition

Annealed 180-240 HB

Heat Treatment

Annealed 180-240 HB

Heat Treatment

| Soft Annealing | Cooling | Stress Relieving | Carburizing | Hardening | Hardness after quenching HRC |

|---|---|---|---|---|---|

| 630°-670°C | Furnace | 150°-200°C | 780°-820°C | Air, oil, salt bath 810°C | 62max |

Tempering °C

| Tempering°C | 100 | 200 | 300 | 400 | 500 | 600 |

|---|---|---|---|---|---|---|

| HRC | 62 | 60 | 60 | 59 | 59 | 58 |