EN-36 Case hardening steel

EN-36 Case hardening steel

Specification

EN-36 is a nickel-chromium-molybdenum based case hardening engineering steel which is precisely designed for carburizing. The incorporation of the nickel increases toughness and shock resistance while the chromium increases the material’s hardenability offering it an even hardness. After being hardened and carburized, EN36 can attain a core strength of up to 1230 N/mm².it’ is used particularly in heavy duty and extremely stressed applications because of its toughness, hardenability, and high core strength. EN36 also provides superior fatigue resistance.

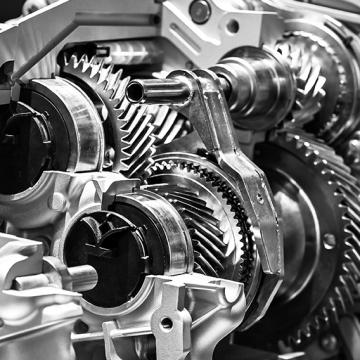

Application

Connecting rods with case hardened ends, Aircraft and automotive crankshaft, Highly stressed gears, collets, and gudgeon pins, Heavy duty gears, ring gears, Couplings and shafts, Heavy duty bushes, Ball and roller bearings.

Chemical Analysis %

| C | Mn | Cr | Si | Ni | P | S |

|---|---|---|---|---|---|---|

| 0.12-0.18 | 0.30-0.60 | 0.60-1.10 | 0.10-0.35 | 3.00-3.75 | 0.045Max | 0.045 Max |

Annealed 255 HB max

Heat Treatment

| Soft Annealing | Cooling | Stress Relieving | Carburizing | Case Hardening | Quenching | Hardness after quenching HRC |

|---|---|---|---|---|---|---|

| 640°-650°C | Furnace | 610°-690°C | Pack, salt or gas carburize at 880°-930°C | 780°-820°C | Air, salt bath 850°-880°C Oil 760°-780°C | 60 |

Tempering °C

| Tempering°C | 100 | 200 | 300 | 400 | 500 | 600 |

|---|---|---|---|---|---|---|

| HRC | 60 | 52 | 51 | 54 | 56 | 50 |