EN19 Steel | SAE 4140 | 1.7225 | SCM440 | 42CrMo4

EN19 Steel | SAE 4140 | 1.7225 | SCM440 | 42CrMo4

Specification

En19 steel is a high-quality engineering alloy steel containing chromium and molybdenum. It falls in a class of low alloy steel. It has high fatigue strength, abrasion and impact resistance, toughness, and torsional strength. It can be heat treated in a number of ways to give it a combination of properties.

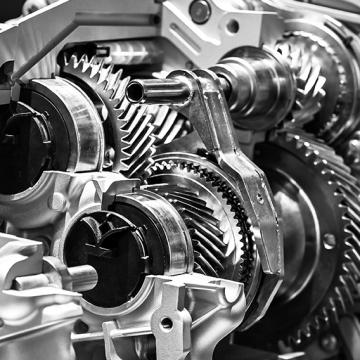

Application

EN 19 steel is a alloy structural steel, EN 19 is used for engineering structural, use in Machine tool and automotive industries gear, gears, shafts, spindles, gears, bolts, studs and a wide variety of applications where a good quality high tensile steel grade is suited.

Chemical Analysis %

| C | Mn | Cr | Si | MO | P | S |

|---|---|---|---|---|---|---|

| 0.35-0.45 | 0.50-0.80 | 0.90-1.50 | 0.10-0.35 | 0.20-0.40 | 0.045Max | 0.045Max |

Delivery condition

Annealed 180-220 HB

Heat Treatment

Annealed 180-220 HB

Heat Treatment

| Soft Annealing | Cooling | Stress Relieving | Hardening | Quenching | Hardness after quenching HRC |

|---|---|---|---|---|---|

| 680°-720°C | Furnace | 600°-650°C | 540°-680°C | Air, oil, salt bath 820°-860°C | 50 MAX |

Tempering °C

| Tempering°C | 100 | 200 | 300 | 400 | 500 | 600 |

|---|---|---|---|---|---|---|

| HRC | 49 | 48 | 48 | 47 | 47 | 46 |