EN24 Steel-AISI 4340 | 1.6511 | 36CrNiMo4 | 40CrNiMo

EN24 Steel-AISI 4340 | 1.6511 | 36CrNiMo4 | 40CrNiMo

Specification

Nickel chromium molybdenum high tensile steel, good wear and shock resistance and is suitable for tensile ranges up to 1550N/mm², ASTM EN24 steel is an alloy structural steel, EN24 is used for engineering structural, Used as require good toughness, high strength, as well as the important conditioning of large size.

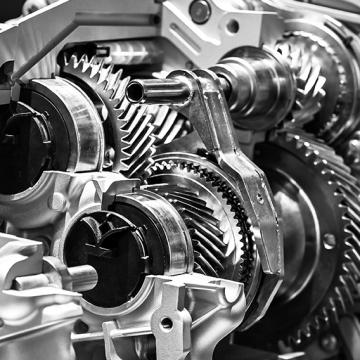

Application

heavy machinery such as high load of axial, turbine shaft, larger than 250 mm in diameter of helicopter rotor shaft, turbojet engine turbine shaft, blade, high load of transmission parts, fasteners of the crankshaft. Gear, Can also be used for operating temperature over 400 ℃ of rotor shaft and blade, etc, And after nitriding processing can also be used to make special performance requirements of the important parts, after low temperature tempering or can be used for ultra-high strength steel after isothermal quenching.

Chemical Analysis %

| C | Mn | Cr | Si | MO | Ni | P | S |

|---|---|---|---|---|---|---|---|

| 0.35-0.45 | 0.45-0.70 | 0.90-1.40 | 0.10-0.35 | 0.20-0.35 | 1.30-1.80 | 0.045Max | 0.045Max |

Annealed 180-220 HB

Heat Treatment

| Soft Annealing | Cooling | Stress Relieving | Hardening | Quenching | Hardness after quenching HRC |

|---|---|---|---|---|---|

| 650°-700°C | Furnace | 630°-650°C | 830°-850°C | Air, oil, salt bath 520°-550°C | 62 max |

Tempering °C

| Tempering°C | 100 | 200 | 300 | 400 | 500 | 600 |

|---|---|---|---|---|---|---|

| HRC | 61 | 60 | 60 | 59 | 59 | 58 |