Plastic Moulding Steel

P-20 1.2311 Plastic moulding steel

Specification

1.2311 is commonly supplied in the hardened and tempered condition with a supply hardness of approximately280 to 325HB, This steel gives an excellent polished finish and is one of the most widely accepted specifications for machine cut plastic moulds and zinc die casting dies. This grade gives excellent wear resistance but if maximum surface hardness is required for compression moulding plastic dies or similar tools, the steel can be case hardened or nitrided.

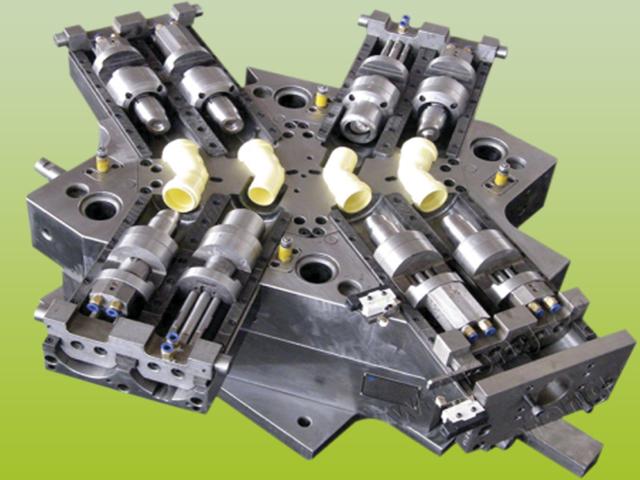

Application

Plastic moulds, mould frames for plastic moulds and pressure casting moulds and recipient sleeves.

Chemical Analysis %

| C | Mn | Cr | Si | Mo | P | S |

|---|---|---|---|---|---|---|

| 0.35-0.45 | 1.30-1.60 | 1.80-2.10 | 0.20-0.40 | 0.15-0.25 | 0.030 Max | 0.030 Max |

Delivery condition

Hardened Tempered 280- 325 HB and

Heat Treatment

Hardened Tempered 280- 325 HB and

Heat Treatment

| Soft Annealing | Cooling | Hardness | Hardening | Quenching | Hardness after quenching HRC |

|---|---|---|---|---|---|

| 720-750°C | Furnace | 235 HB | 840-870°C | Oil or thermal bath, 180-220°C | 51 |

Tempering °C

| Tempering°C | 100 | 200 | 300 | 400 | 500 | 600 | 700 |

|---|---|---|---|---|---|---|---|

| HRC | 51 | 50 | 48 | 46 | 42 | 36 | 28 |